The Challenge of Choosing the Right Profile

Walk into any electronics lab, and you’ll see engineers grappling with EMI (electromagnetic interference) headaches: an enclosure that won’t quite seal, a signal that keeps leaking, or a foam gasket that compresses incorrectly under heat. At first glance, EMI gaskets may all appear similar—until a project demands precise shape profiles for both environmental sealing and signal attenuation. That’s when small design choices become significant pain points.

Here at JEMIC, we know that not every gasket is created equal. Different shapes—D, R, L, and P—bring unique compression properties, geometries, and sealing capabilities. By understanding what each shape does best, you can confidently pick a gasket that prevents interference, seals out contaminants, and endures the conditions of your specific application.

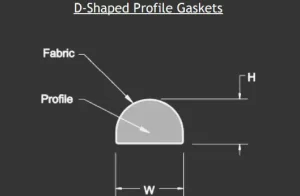

How Do D-Shaped EMI Gaskets Solve My Sealing and Shielding Issues? Why the “D” Profile Stands Out

D-shaped gaskets are often the first choice for engineers needing a low-profile seal that’s highly effective against interference. They feature a rounded top (shaped like the letter “D”) that compresses smoothly under load. This design has a stable contact area and is straightforward to install along enclosure edges or door frames.

Key Advantages of D-Profile

- Uniform Pressure Distribution:The arc shape tends to compress evenly, which helps maintain consistent contact with mating surfaces.

- Common Dimensions:Standard D-profiles, such as PD1425 or PD2538, fit many enclosure gaps without requiring custom widths or heights.

- Quick Installation:The simple cross-section means fewer alignment or orientation challenges.

When to Consider a D-Gasket

If your project involves mid-range compression requirements and you need a shape that balances mechanical stability with efficient EMI shielding, D-shaped gaskets are a robust option. They also work well when you want a moderate footprint and no harsh corners that might catch or tear during assembly.

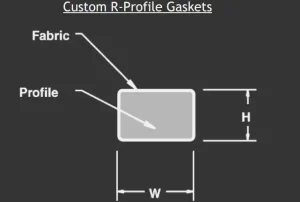

Is an R-Shaped Gasket Right for More Complex Geometries? Recognizing the R-Profile’s Strengths

The R shape offers a more rounded cross-section than the D—like a half-circle or cylindrical slice—and is often used in designs that call for tighter sealing or less foam displacement on compression. JEMIC produces R-gaskets in standard sizes (e.g., R0419, R2538) and fully custom variants, which can handle applications with special mounting grooves or unusual enclosure shapes.

Why Engineers Appreciate the R Profile

- Smooth Compression and Recovery:The semi-cylindrical form allows the gasket to “spring back” well, minimizing compression set over repeated cycles.

- Tighter Fit for Certain Slots:R-shaped gaskets can conform to small or curved channels where D or L shapes might pinch or misalign.

- Less Bulk in Clearance Areas:Some enclosures have limited space around corners or internal hardware. An R profile often slides in neatly.

When to Consider R-Gaskets

The R shape typically excels if your product demands a more uniform compression path (for example, in tight-fitting compartments) or if you want excellent rebound properties to handle frequent open-and-close cycles.

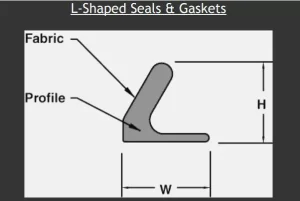

What Makes L-Shaped Gaskets Unique for My Enclosure Design? Where L Gaskets Shine

L-shaped gaskets may not be as commonly discussed as D or R, but they deliver unmatched performance in scenarios where two perpendicular surfaces meet. Picture the corner of a hinged door or an area in your enclosure that needs a vertical and horizontal seal in one strip. The “L” profile hugs those angles without creating gaps.

Top Features of L-Profile EMI Gaskets

- Enhanced Corner Sealing:An L gasket can cover tricky seams that a flat or rounded profile might leave partially exposed by spanning two planes at once.

- Space-Saving Seal: Rather than using two separate gaskets, one on each surface, an L shape merges them into a single strip. This can cut down on assembly time and potential failure points.

- Customizable Dimensions:JEMIC readily adjusts the L’s height and width (like PL3942) to match exact corner or flange requirements.

When to Consider L-Gaskets

You might choose an L-shaped profile if your design calls for sealing an edge or corner while also managing EMI. This profile is especially handy in applications where the enclosure includes a step or overlapping flange—common in racks, door frames, or equipment cases.

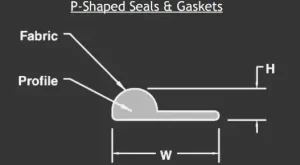

Why P-Shaped Profiles are Ideal for Large Gaps and Firm Sealing: The P-Gasket Advantage

P gaskets resemble a “P” lying on its back, featuring a wide hollow bulb that flattens under compression, plus a narrower base for attachment. They’re often used in places where you need a stronger environmental seal in tandem with EMI shielding—especially if the gap you’re bridging is larger than average.

Distinct Benefits of the P Shape

- High Compression Range:The bulb portion can accommodate larger tolerance variations, making it suitable for uneven surfaces.

- Dual-Seal Capability:Because of the extra cavity, the P profile can create both an EMI barrier and a more robust environmental (dust, moisture) seal.

- Application Flexibility:Options like PP1552 allow you to tackle big enclosures or panels where typical foam strips might not reach or seal effectively.

When to Consider P-Gaskets

This shape is your go-to when you’re dealing with large enclosure gaps, frequently varying compression needs, or even if you need to block out moisture and dust while combating EMI concerns.

How Do I Pick a Shape That Meets My Specific Requirements? Step-by-Step Considerations

- Identify Your Compression Constraints:How tight or loose is the enclosure’s design? Narrow that down to see if you need a smaller cross-section (R or D) or a wider seal (P).

- Check Your Mounting Surfaces:Are you sealing a corner or a joint with perpendicular planes? That’s an L gasket scenario.

- Assess Environmental Sealing Needs:If you require significant dust or moisture protection, consider if the robust bulb of a P profile is necessary.

- Account for Repeatability:A shape with strong rebound (R or L) may be beneficial for applications where doors open and close frequently.

- Look for Proven Attenuation:JEMIC profiles often exceed 85 dB attenuation from 20 MHz to 10 GHz. Confirm your shape won’t compromise these specs.

Why JEMIC is Your Trusted Partner

At JEMIC, our engineering and manufacturing teams don’t just hand over a one-size-fits-all gasket. We engage with you to see how your environment, performance goals, and cost expectations combine to shape the perfect D, R, L, or P solution. Our custom manufacturing processes also let you bundle multiple components into one unified shielding assembly.

Turn Confusion into Confidence: JEMIC Shaped EMI Gaskets

The frustration of dealing with electromagnetic interference can make any design task feel endless—until you land on the right gasket shape that fits perfectly, compresses just enough, and locks out unwanted signals. Whether you’re trying to maintain a lightweight design, fit a tricky corner, or ensure high dust sealing, each profile (D, R, L, or P) has distinct advantages.

By matching your enclosure’s geometry and environmental needs to the optimal gasket profile, you reduce EMI risk and streamline assembly and maintenance. When in doubt, reach out to JEMIC. We’ll help you choose or customize the gasket that elevates your product from vulnerable to confidently shielded—no matter how challenging the interference landscape may be.